Gira is committed to the 1.5°C goal of the United Nations and is playing its part in achieving it.

It is crucial that we meet this goal to ensure the positive development of society and, ultimately, to ensure the future viability of Gira. Together with our partners, we have drawn up a climate balance sheet for 2019 and 2021, which uses scientific scenarios to determine how many degrees the planet would warm up by if all companies were to operate like Gira.

We are currently sitting at 1.7°C in the year 2100, which means that Gira is currently “Paris-compliant”, but not yet at our target of keeping global warming to a maximum of 1.5°C.

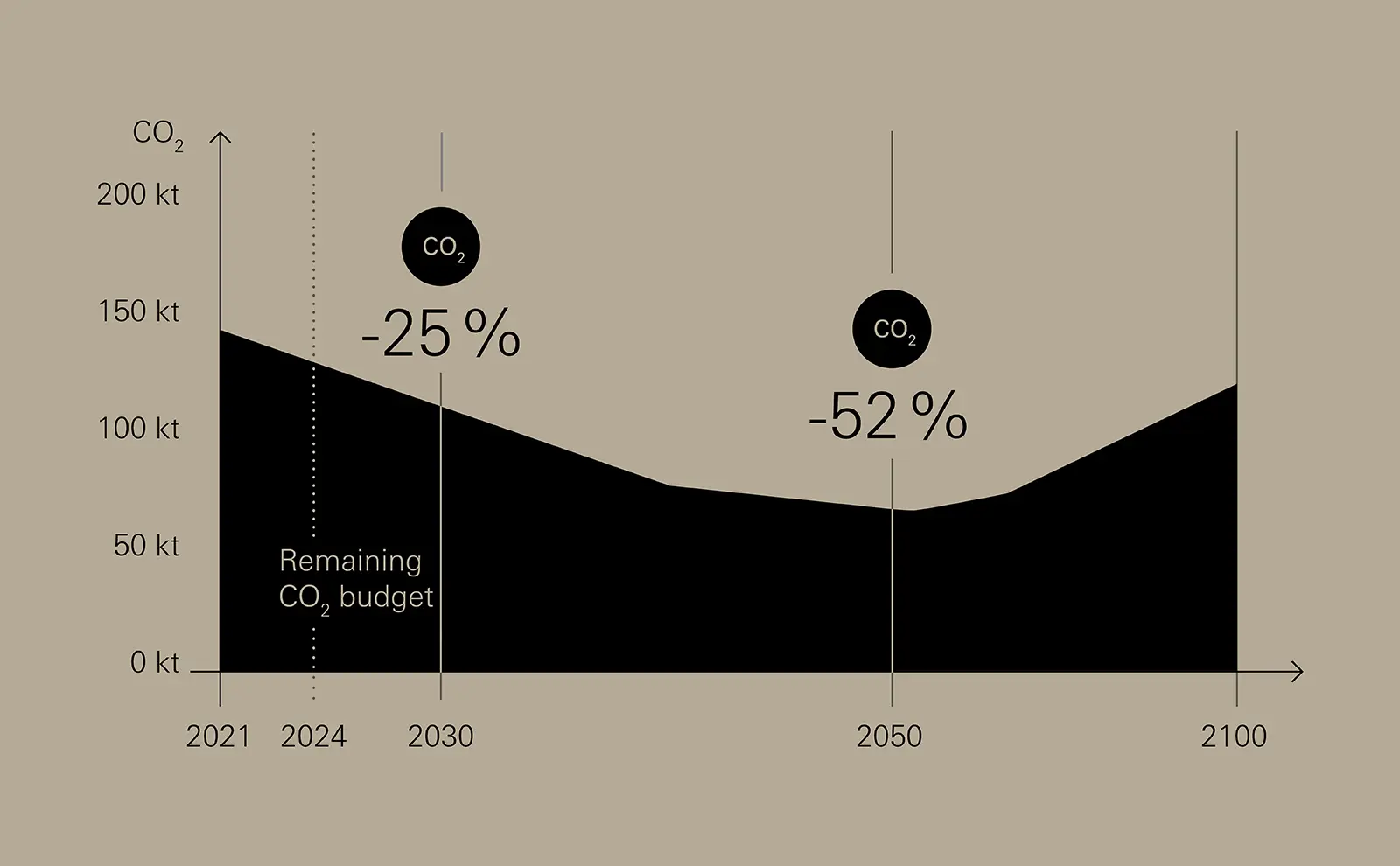

Our climate balance sheet also includes the usage and disposal life cycle phases of our products (scope 3). In order to determine our contribution to the achievement of the goal of 1.5°C, a climate roadmap has been established that sets out our remaining CO₂ budget up to the year 2050. We need to meet, or better still come in below, this budget.

The result for Gira is an agreed annual CO₂ budget up to the year 2050, which we and all of our employees want to adhere to. We will report on our achievement of this in the future. We regularly check and monitor compliance with our objectives with this in mind.

What we do.

The Gira solar park is emerging.

From summer 2025, more than 13,000 photovoltaic modules spread across plots covering a total of 70,000 square metres are expected to produce around 9.8 million kilowatt hours of electricity each year. This is roughly equivalent to the energy consumption of 2500 four-person households. We want to start by using approximately half of the electricity generated ourselves and aim to increase this share to as much as 70% by optimising our operations. This is another step towards independence from fossil energy sources and will bring about a significant reduction in the greenhouse gas emissions at our Radevormwald site as part of the Gira climate strategy.

Find out more about the project process.

More efficient and circular building.

The Gira Campus on Röntgenstraße, which was inaugurated in 2018, was built in accordance with the cradle-to-cradle approach so that it can grow alongside the company to around 50,000 square metres before being disassembled into its constituent parts at the end of its service life. Thanks to a sophisticated energy concept, its energy consumption is 45% lower than the requirements set out in the German Energy Saving Ordinance (EnEV) at the time it was built. This was achieved through combined heat and power plants, thermally activated floors and sprinkler tanks that serve as cold and heat storage.

Energy management in accordance with ISO 50001:2018.

Here at Gira, we use an energy management system (EnMS) to continuously improve our energy performance by reducing our energy consumption and increasing our energy efficiency. To this end, we measure and document the effectiveness of the optimisation measures we have introduced and are certified to ISO 50001:2018.